How is the support bar of the cold shrinkable cable accessory made?

【Abstract】: Cable accessories are equipment that can be used in the middle of the cable body to connect or connect cable terminals and transmission line equipment. Generally, 1-35KV cable accessories are currently used in many types of cold-shrinkable cable accessories, cold-shrinkable cables. In fact, the main processes of making the support strip of the accessory include crimping, ultrasonic welding and hot air welding. Today, the editor will explain to you how to make the support bar of the cold shrinkable cable accessory? |

Cable accessories are devices that can be used to connect in the middle of the cable body or connect cable terminals to transmission line equipment. Generally, 1-35KV cable accessories are currently used in many types of cold-shrinkable cable accessories, and the support bar of cold-shrinkable cable accessories In fact, the main processes for making it are crimping, ultrasonic welding, and hot air welding. Today, the editor will explain to you how to make the support bar of the cold shrinkable cable accessory?

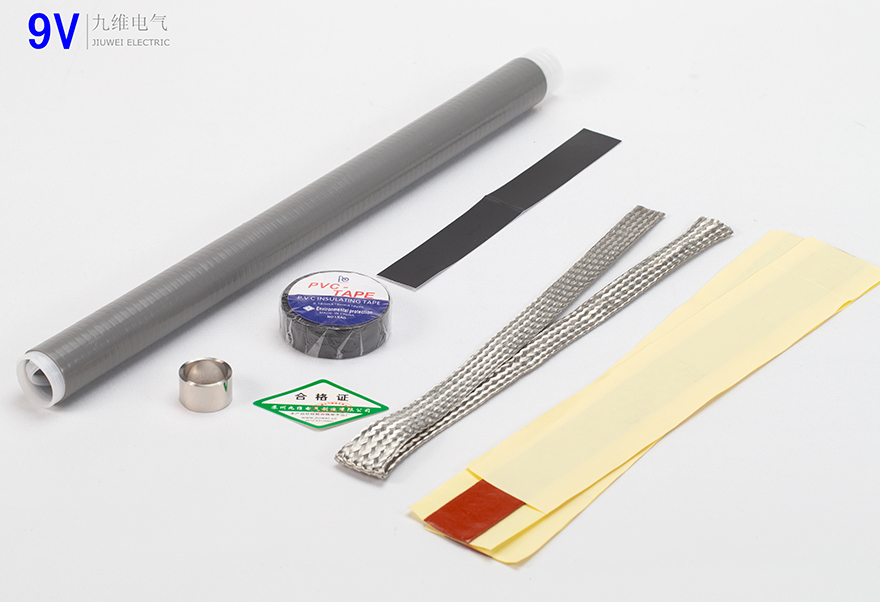

The support strip of cold shrinkable cable accessories is made of polypropylene as raw material, extruded into strips with occlusal clips, and then uses a special machine to crimp the clips to form a cylinder with a specific inner diameter, cut it to a specific length, and use a welding torch at both ends. Solder it on, do not let it loose. After expanding the various components of the cold-shrinkable cable accessories, put one end back through the inside of the support bar to make a stretching head, that is, spare the lead during installation, and then put the lead After the end of the cable is welded, it is made into a finished cold shrinkable cable accessory product.

We know that the price of PP material is relatively low, but the strength will be relatively large, the production is relatively simple, and the mechanical equipment is also very simple. is well controlled. However, if the manufacturing process is not perfect, improper selection of materials may cause the support bar to loosen and be very weak, so that the entire cold shrinkable cable accessory fails and cannot be installed. At the same time, the manufacturing process is very cumbersome and labor-intensive. To achieve mechanized and automated continuous production, when winding the tube, instead of using self-clinching and crimping, ultrasonic waves are used to melt local PP raw materials to form melting points and bond together, and no special spot welding is required before the stretching head.

When we make it according to the above method, it will save labor costs, the connection strength of the solder joints is high, and the support bars are not easily deformed. It can be transformed into continuous automatic production, but sometimes it will affect the installation of users. Experience, so a good quality support strip can add a lot of color to the products of cold shrinkable cables. From the current market point of view, there are generally three processes for the production of cold-shrinkable support bars, crimping, ultrasonic welding, and hot air welding. These processes are widely used in crimping and ultrasonic waves, and there are relatively few hot air welding manufacturers. In short, each has its own advantages and disadvantages. The main reason is that the support bar will be extracted during use. As long as the product is deformed before use, it is easy to use and the cost is low. It can be pulled.

Hotline: +86 18001554818 / +86 18068406516