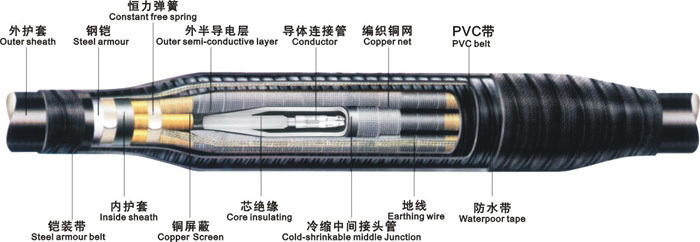

Heat shrinkable straight joint installation process

Last time, I talked about the indispensableness of power intermediate joints in the connection between cables and cables, and also explained in detail the perfect installation method of cold-shrinkable cable intermediate joints, although cold-shrinkable products in cable accessories have now become the most important part of power installation. Preferred, but in some cases heat shrink is a better choice. In the actual power installation, it does not matter whether the middle connector of the cold shrinkable cable or the middle connector of the heat shrinkable cable is selected. Their construction procedures are not careless and perfect installation is an important guarantee for the safety and stability of power transmission.

Next, I will explain to you how to install the heat shrinkable cable intermediate joint to ensure the most perfect connection of power (a complete installation tutorial video is attached below)

1. Preparations before installation:

a: It should be noted that the installation site is free of dust and maintains a dry and ventilated environment.

b: Check whether the installation tools are complete.

c: Check whether the cable accessories match the cable.

d: Straighten and saw both ends of the two cables to be connected.

2. Stripping

a: Strip according to the size of the installation instructions

b: Peel off the outer sheath in turn, leave (30mm) at both ends of the steel armor and the rest, and leave (50mm) at each end of the inner sheath, and remove the rest, remove the filler (reserved for use), and separate the three phases.

c: After measuring the length of 310mm, fix it with PVC tape, peel off the copper shield, keep the 50mm semi-conductive layer, and cut off the rest.

d: Grind the surface of the remaining steel armor and clean the outer sheath.

e: Grind the outer sheath and the inner sheath.

f: Cut off the insulating layer by adding 3mm to 1/2 the length of the connecting pipe.

g: Polish the surface of the insulating layer with fine sandpaper. Remove residual semiconducting particles.

h: Clean the main insulating layer, fill the steps between the outer semiconducting layer and the insulating layer with stress relief glue, and apply a layer of silicone grease.

i: Insert the stress tube, overlap the outer semi-conductive layer by 20mm, and fix it by heating and shrinking.

j: Sleeve the pipe and the copper mesh in sequence: Sleeve the sheath on both ends of the cable respectively, and insert a set of inner insulating tube, outer insulating tube and semi-conductive tube on each phase of the long end of the cable.

k: Put the copper mesh on the short end of the cable respectively.

3. Install the connecting pipe

a: Sleeve into the connecting pipe and perform crimping. When crimping, it should be crimped to both sides according to the middle of the connecting pipe.

b: After the crimping is completed, file the edges and corners and burrs on the connecting pipe and clean the connecting pipe.

c: Wrap the semi-conductive tape on the connecting tube and overlap the inner semi-conductive layer by 5mm.

d: Wrap filling glue and insulating self-adhesive tape on the semi-conductive tape to make the transition between the connecting tube and the main insulation smooth.

e: Use cleaning paper to clean the outer surface of the insulating layer and the stress tube, first fill the step between the stress tube and the main insulating layer with stress release glue, and overlap 5-10mm. And evenly apply a layer of silicone grease on the insulation, stress tube and connecting tube.

4. Install heat shrinkable insulating tube

a: Place the three inner insulating tubes in the center of the connecting tube, and heat and shrink from the middle of the inner insulating tube to both ends. Then place the three outer insulating tubes in the center of the inner insulating tube, and heat and shrink from the middle to both ends.

b: From the copper shielding port, the end face of the outer insulating tube is wrapped with sealant to fill the gap. Wrap around into a cone. The semi-conductive tube is placed in the center of the outer insulating tube, and heated to shrink.

c: Use semi-conductive tape to wrap copper shield and semi-conductive tube at the overlap of 10mm.

d: The stretched copper mesh is covered on the semi-conductive tube, and the two ends are overlapped on the copper shield of the cable.

e: Fix the ground wire together with the copper mesh on the copper shielding layer with a constant force spring, and wrap the PVC tape around the constant force spring.

5. Sealing treatment

a: The three phases are arranged together, the filler is restored, and it is fixed with PVC tape.

b: Connect the steel armor at both ends of the cable with a ground wire and fix it with a constant force spring, fix the constant force spring with PVC tape, and wrap the filling glue on the constant force spring and the outer sheath to fill the gap.

c: Wrap the sealant at 50mm on the outer sheath layer.

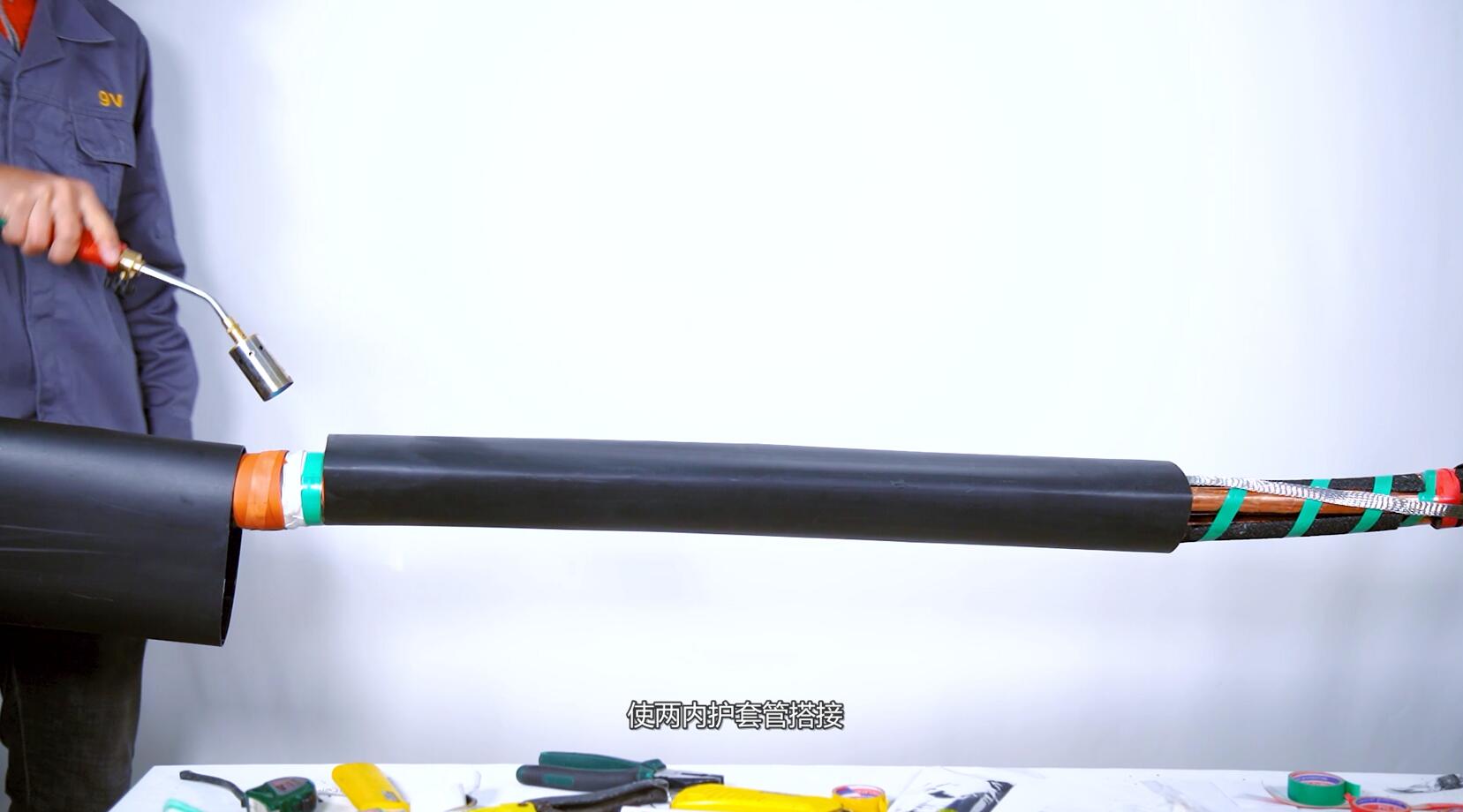

d: Wrap the sealant on the outer sheath and the inner sheath at both ends of the cable, and heat and shrink one end of the inner sheath to overlap the inner sheath, so that the two inner sheaths are overlapped.

6. Install the outer sheath

a: Lap one end of the outer sheath with the outer sheath of the cable for 100mm respectively, and heat and shrink to fix it.

7. Installation finish, clean up the site.

Please watch the full video:

Hotline: +86 18001554818 / +86 18068406516