System introduction of heat shrinkable sleeve

Heat shrinkable sleeve is a kind of polyolefin plastic tube processed by special production processes such as radiation cross-linking. This technology was developed and manufactured by the industry leader Raychem Corporation of the United States. It was introduced by a research institution in Changchun in the mid-1990s and spread rapidly in China. This issue will briefly introduce you from the application principles, raw materials, manufacturing processes, and types of applications.

1. Application principle

(1). Expansion principle of heat shrinkable sleeve: Generally, a high-energy electron beam accelerator is used to properly cross-link the polymer segments of the pipe to form a network structure. When the pipe is heated above the glass transition temperature TG, the pipe is softened, the internal polymer segments are activated, and the inner diameter of the pipe is expanded to a certain extent by means of external force, because the medium and polymer segments of the network structure can be deformed through expansion and contraction. To offset such external force, it will not break the chain segment, just like a rubber band, but when we expand it, quickly let the pipe cool down to below the glass transition temperature TG, the pipe will become hard after expansion, and the internal high The molecular segment will lose its activity due to the weakening of low temperature energy, and cannot change its posture at will. In this way, the segment isfrozen; and the shape stabilizes after expansion. At the same time, it should be pointed out that the reaction force of the internal polymer segment itself corresponding to the external force will not disappear, forming an internal stress, which is balanced by the retraction resistance after being frozen.

(2). Shrinkage principle of heat shrinkable sleeve: After the heat shrinkable sleeve is heated at high temperature, the temperature of the tube rises above TG, so that the polymer segment is activated again, and the internal stress will break the previous balance and begin to guide the segment to recover before expansion. Shape. From a macro perspective, after the heat shrinkable tube is heated, the diameter of the tube continues to shrink until it returns to its original size, or stops shrinking when it encounters other resistance. Kind of like a loose rubber band. This is the most basic general principle of heat shrink tubing.

2. Raw materials

There are still many raw materials that can make heat shrinkable sleeves, and they are basically polymer polyolefins. Among them, polyethylene (PE) is the main one. Usually, the heat shrinkable tube is this type of heat shrinkable tube. The heat shrinkable tube of other materials needs to be specified. The heat shrinkable sleeve of the Iphone mobile phone we mentioned at the beginning is this type. Of course, there are other materials that can also be made into heat shrinkable tubes, such as PVC, PET, PVDF, EPDM, silicone, EVA, etc., but the production principles of PVC and PET heat shrinkable tubes are different.

3. Manufacturing process

The production process of PE heat-shrinkable sleeve generally goes through the process stages of batching, extrusion, irradiation, expansion, and packaging, of which batching and irradiation are the most critical links.

(1). Mixing: It is to mix the raw materials of the set formula, and then mix with an internal mixer to produce the master batch particles required for the heat shrinkable sleeve.

(2). Extrusion: put the master batch into the internal mixer, and extrude qualified pipes according to a certain process. During the extrusion process, the wall thickness and partial wall condition of the pipe have a great influence on the quality of the heat shrinkable sleeve.

(3). Irradiation: The above-mentioned pipe is irradiated by an electron accelerator, so that the cross-linking degree of the polymer material inside the pipe is increased, and it becomes a network-like structure. There are chemical bonds between the segments and the segments are linked, and there is a strong interaction. force. The radiation cross-linking process is the most critical process in the manufacture of heat shrinkable tubes. The degree of radiation cross-linking must be suitable to produce qualified heat-shrinkable tubes. If the radiation cross-linking is too large, the tube cannot be expanded. If the crosslinking is too small, the tube cannot be expanded, or cannot be expanded to a larger multiple, and it is easy to crack, and the shrinkage force of the manufactured heat shrinkable tube is not enough, and the shrinkage effect is not good. Therefore, it is necessary to formulate appropriate irradiation process parameters for each product in order to manufacture qualified heat shrinkable tubes.

(4). Expansion: The pipe after irradiation and cross-linking can be preheated to a higher temperature and expanded by external force to increase the diameter of the pipe, and then rapidly cooled to room temperature, so that the shape of the pipe after expansion is finalized. , The main principle of this process is that the activity of high segment segments of the pipe after irradiation cross-linking has a great relationship with the temperature. In a certain high temperature range, the resistance of segment activation and segment extension and bending is very small. The tube is like an elastic mesh that can be stretched by external forces, so heating to this temperature range can easily expand the tube. When the temperature drops rapidly, usually around room temperature, this activation phenomenon will be lost, the resistance of the chain segment to stretch and bend is very large, and the internal stress of retraction is not enough to overcome this resistance, so in the natural state, the expanded shape.

4, types of applications

Heat shrinkable tubes have been widely used in electric power, electrical, military, civil and other fields. The main purpose is insulation protection, waterproof sealing, anti-skid and anti-rust.

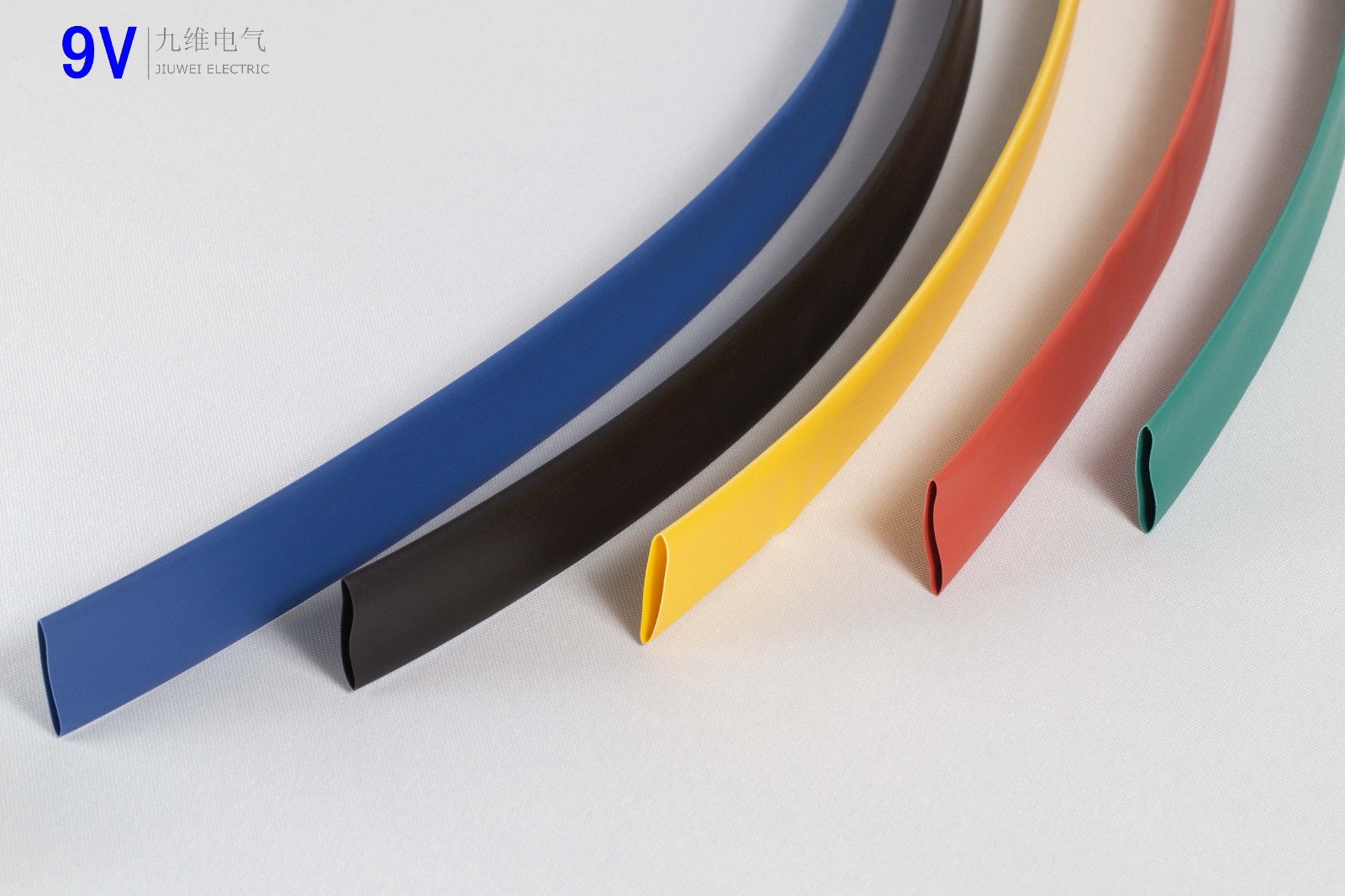

The main product series are:

(1). Thin-walled heat-shrinkable tube: thin-walled heat-shrinkable tube with a small diameter, suitable for insulation protection of low-voltage wires and cables and wiring harnesses of electronic products.

(2). Double-wall tube with glue: with a layer of co-extruded hot-melt glue, suitable for insulation and sealing protection of low-voltage wires and cables, with good waterproof performance.

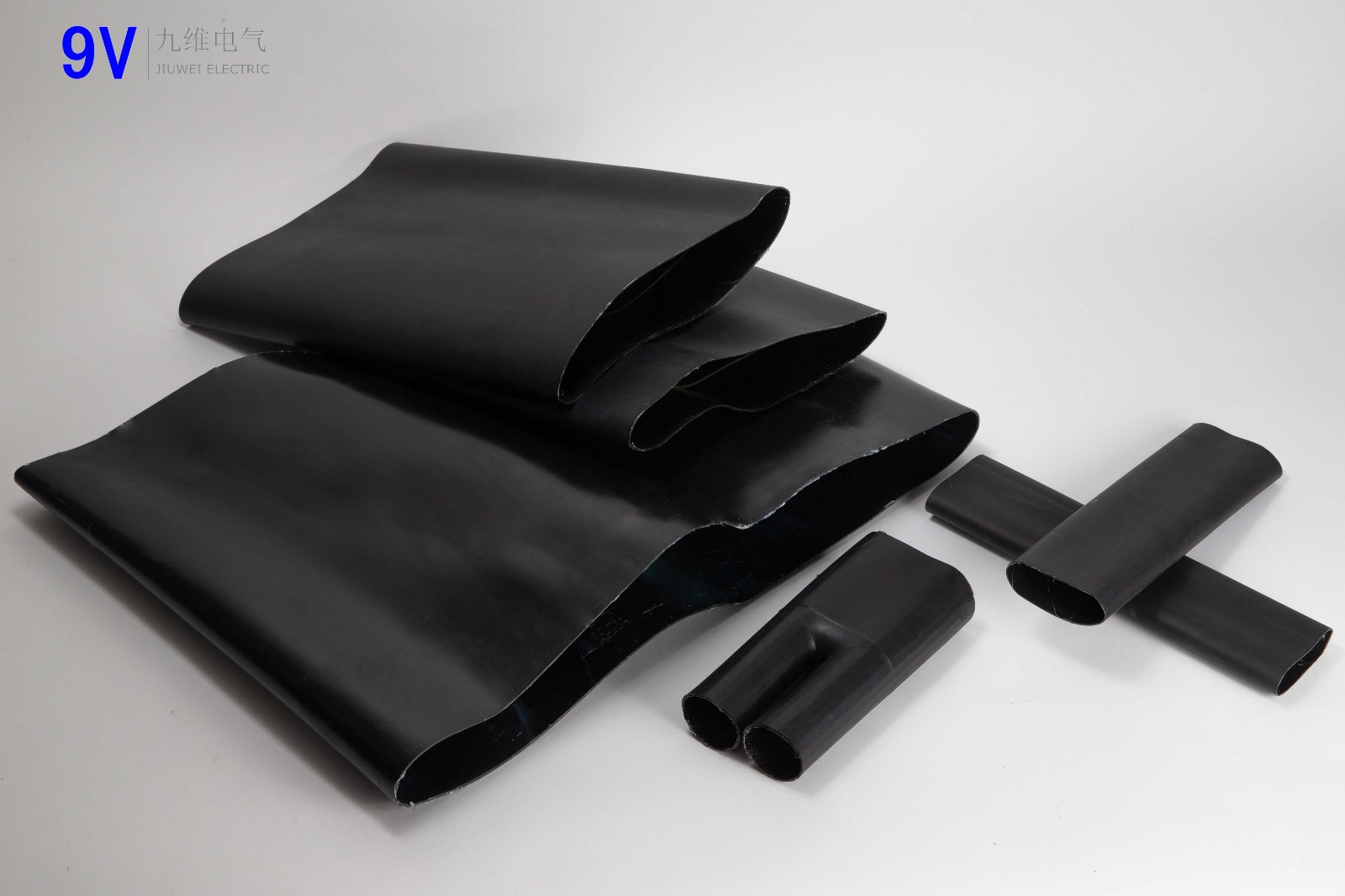

(3). Busbar heat shrinkable tube: insulation protection for high and low voltage busbars.

(4). Medium-thick wall sheathing: for the protection of medium and high voltage cables and other mechanical equipment, hot-melt adhesive can be applied inside, which greatly improves the waterproof and sealing performance.

(5). Heat-shrinkable cable accessories: used for intermediate joints and terminal heads of high and low voltage cables, which are composed of various heat-shrinkable components and other accessories. Such as heat shrinkable finger sleeves, umbrella skirts, etc.

(6). Special heat shrinkable tube: such as fishing rod pattern tube, sign tube, etc.

(7). Heat shrinkable tubes of other materials: PVC heat shrinkable sleeves and PET heat shrinkable sleeves are more suitable for battery outer packaging.

Hotline: +86 18001554818 / +86 18068406516