Application of Heat Shrinkable Sleeve Protection Technology in Substation

This paper describes the concept, performance characteristics and application of the new type of heat shrinkable sleeve, and puts forward the problems that should be paid attention to in the implementation of insulation protection in substations.

1. The concept of heat shrinkable sleeve

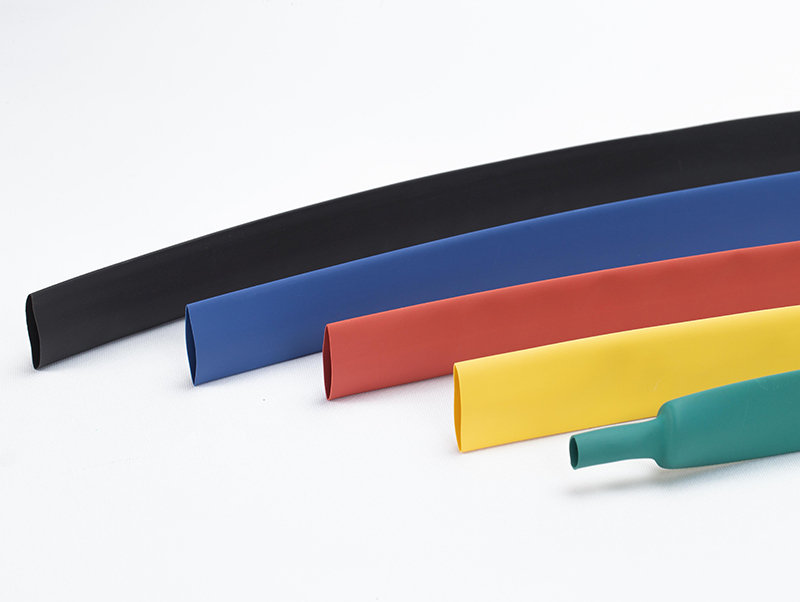

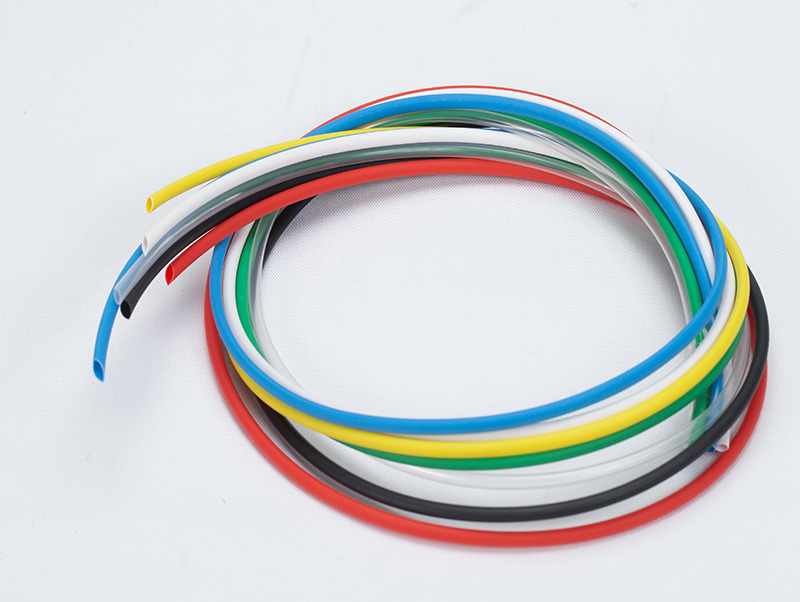

Heat-shrinkable sleeve: a tubular intermediate product with a specified size is obtained by extruding a plastic linear polymer, and after irradiation and cross-linking, it is heated to expand, and cooled and shaped to obtain a tubular product with a certain size and elastic memory. Use heat shrinkable sleeve for insulation protection, which can be closely combined with the conductive busbar and firmly attached to the conductor surface, so as to achieve the purpose of insulating the charged body.

2 Technical performance analysis

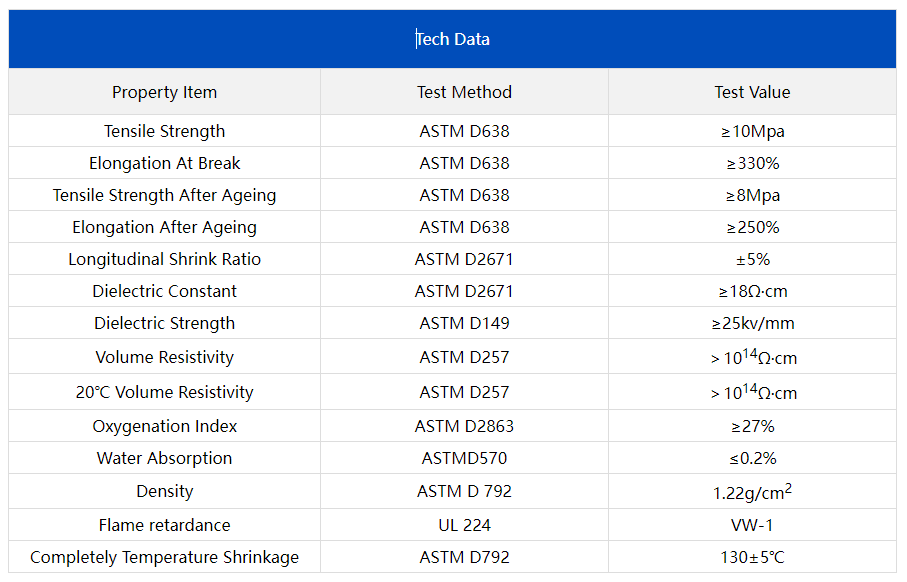

2. 1. Jiuwei heat shrinkable sleeve performance parameters

2. 2. Flame retardant properties of heat shrinkable materials

Insulation materials for power equipment are required to be flame retardant. The heat shrinkable materials are mainly composed of rubber-plastic blended polymers, and flame retardants with excellent performance are added. They have good self-extinguishing properties from fire, and can meet the flame retardant requirements of power systems.

2. 3. Aging resistance of heat shrinkable materials

According to the principle of heat shrinkage, heat shrinkage essentially originates from the cross-linked structure of the internal network, and it is for this reason that the anti-aging properties of heat shrinkable materials are superior to other insulating materials. The accelerated aging experiment of the heat shrinkable material by the Shanghai Electric Cable Research Institute shows that the thermal aging life of the material can reach 20 years, and the heat shrinkable material used on artificial satellites has been running normally for 21 years.

2. 4. Temperature resistance of heat shrinkable materials

Due to the special microscopic nature of the heat-shrinkable material, the material has been subjected to a thermal aging test of 158 ℃±2 ℃ for 168 h, and the performance has no major change (for the series of heat-shrinkable materials for substations). Generally speaking, the limit working temperature of substation busbar is 70 ℃. Therefore, it can meet the requirements of substation operation on its temperature resistance characteristics.

3 Applications

The application of heat shrinkable sleeves to substation insulation protection can solve many practical problems.

(1) Effectively prevent short-circuit failure of small animals

(2) Prevent pollution flashover, condensation flashover, icing and other tripping accidents

(3) Effectively prevent personal injury accidents

(4) Prevent the corrosion and corrosion of the busbar by salt spray and harmful chemical gases.

4 Notes on application

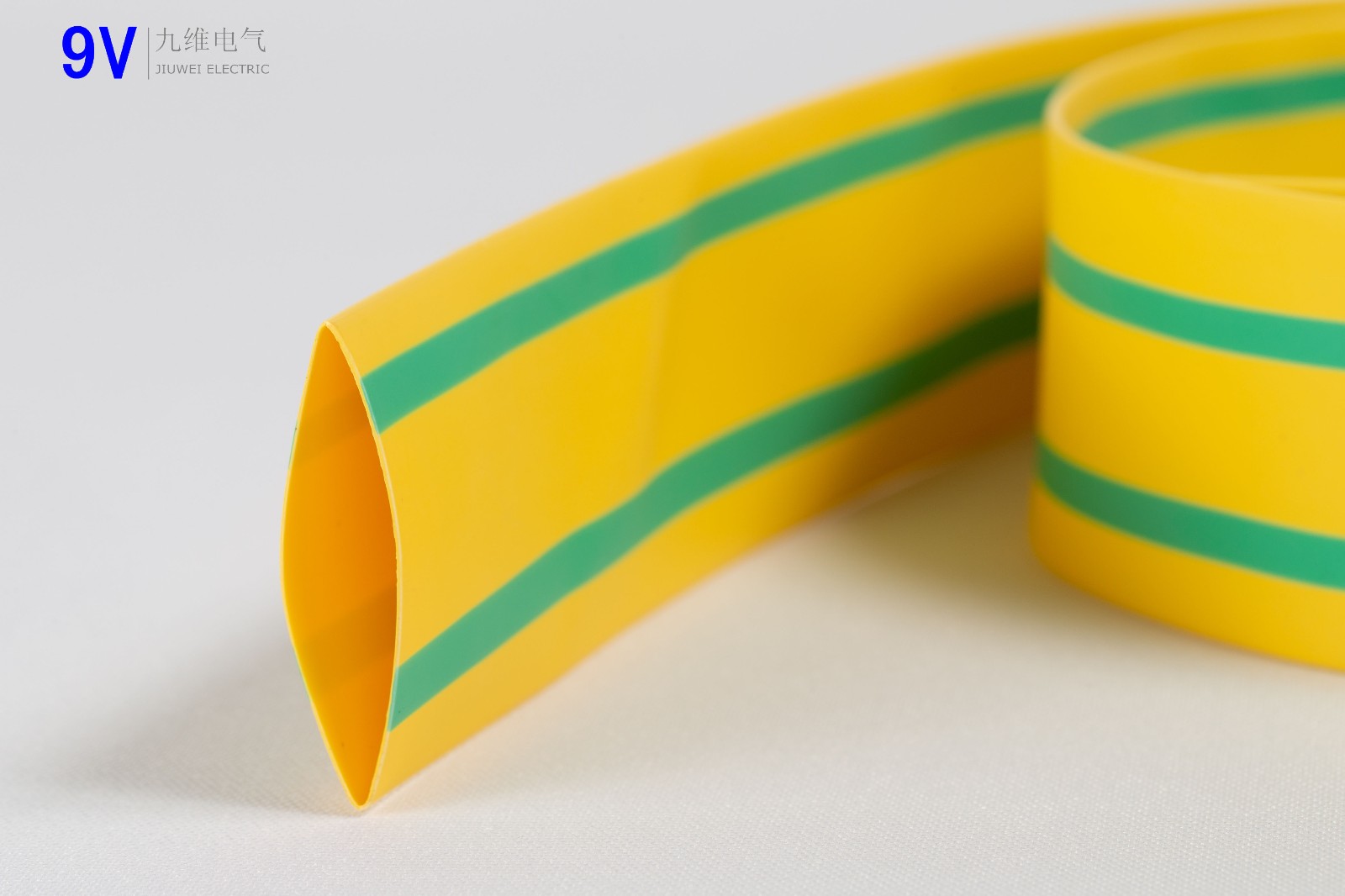

(1) Choose different heat shrinkable materials according to different substation facilities.

For the exposed busbar, the busbar insulating sleeve can be selected, and the composite insulating heat shrinkable tape can also be used. The former must dismantle the busbar, which is difficult to construct and takes a long time, but it is beautiful after treatment; the latter does not need to dismantle the busbar, the construction is easier and the time is short. Users can choose according to the actual situation. If the new substation has not been put into operation and the time is sufficient, the busbar insulation bushing method can be adopted, and the old substation renovation time is limited, and the composite insulation heat shrinkable tape method can be considered.

An insulating joint protection box can be used at the busbar joint or at the joint with the bushing. Since the joints often need to be disassembled, the insulating protective box can be flexibly opened and closed for easy maintenance. Do not use insulating sleeves or heat shrinkable tapes to fix them.

(2)) About heat treatment

The insulating sleeve or heat shrinkable tape can only shrink on the surface of the charged body by heat treatment. Therefore, the heat treatment process is not only related to the life of the material, but also related to safety. Heat treatment should pay attention to the following points:

①Appearance: After heating, it should be smooth and uniform, and the wall thickness after shrinkage should not exceed 3mm.

② Heat shrinkage: No matter whether the sleeve or the heat shrinkable tape is used, it should be ensured that the shrinkage is in place, and there is no air gap left in the middle, otherwise it will cause heat to affect the life, especially the corners should be carefully handled to ensure it is in place.

③Connection treatment: The treatment of heat shrinkable sleeve or heat shrinkable tape connection is very important. The heating time of the connection must be long enough to ensure its heat shrinkage and smooth transition, so as to ensure the same electrical performance of the front and rear sections and the connection.

(3) It is necessary to leave the remaining busbar live test position: it is convenient for power test grounding during maintenance. The location of the ABC three-phase power inspection must be selected according to the actual situation on site. The three-phase positions of A, B, and C should be in a triangle shape, and should be as far away from the supporting insulator as possible to prevent the flashover of the charged body to the porcelain bottle, see Figure 1.

5 Application prospects

According to the2021-2025 Development Prospects and In-depth Research and Analysis Report of China's Heat Shrinkable Sleeve Industry; released by the China Research Institute of Puhua Industry:

Heat shrink tubing has unique advantages. In recent years, it has been widely adopted in sectors such as electronics, electricity and household appliances.

In addition to the above-mentioned protection of busbars in substations, it is often used in our real life. For example, in the communication industry, it can be used to strengthen the connection strength, electrical characteristics and tightness of the connection between cables; in refrigerators, heat shrinkage The tube can strengthen the connection strength and tightness of the copper-aluminum joint of the refrigerator; in the copier, the heat shrinkable tube can enhance the connection strength of the electrical connection and improve its insulation resistance and withstand voltage, etc.

The heat-shrinkable marking tube is based on the heat-shrinkable tube and has undergone special treatment to make its surface suitable for precise and firm typing. Its core value is permanent marking.

6 Conclusion

Heat shrinkable materials are used in the insulation protection of substations, which fundamentally solves the problems of small animal short circuit, salt spray corrosion, pollution flashover, arc discharge, etc. It is a practical and effective measure for the renovation of old substations.

It has been verified by tests that the material has good insulation properties, thermal conductivity, flame retardancy, aging resistance and temperature resistance, and can be used for insulation protection of exposed conductors such as switch cabinets and bus bars in substation switch rooms. It can also be used for insulators to increase creepage. distance and prevention of pollution flashover, etc. As long as attention is paid to the selection of qualified products in use, and the construction is carried out in strict accordance with the construction process requirements during installation, the heat shrinkable material will definitely play a good role in insulation protection.

Although my country has not developed and produced heat shrinkable tubes for a long time, it has developed rapidly. In RF connectors, it is mainly used to strengthen the connection between connectors and cables, in low frequency connectors as an alternative insulator, and heat shrink tubing can also be used as a seal in the connector. Heat shrinkable tubes are also widely used in other industries of the national economy. In a word, the application field of heat shrinkable tube can be said to penetrate into all sectors of the national economy, and it is a promising emerging industry.

Hotline: +86 18001554818 / +86 18068406516