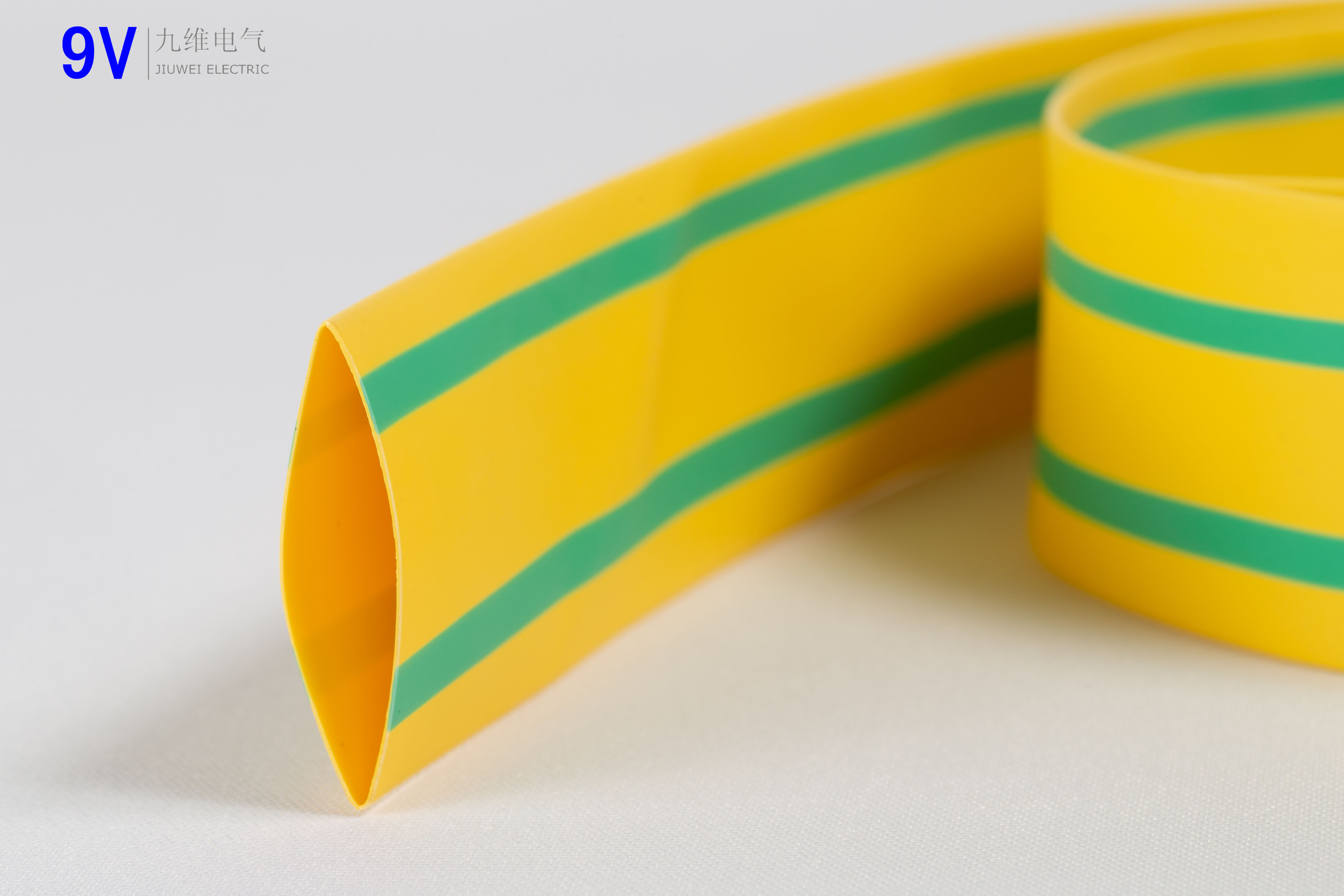

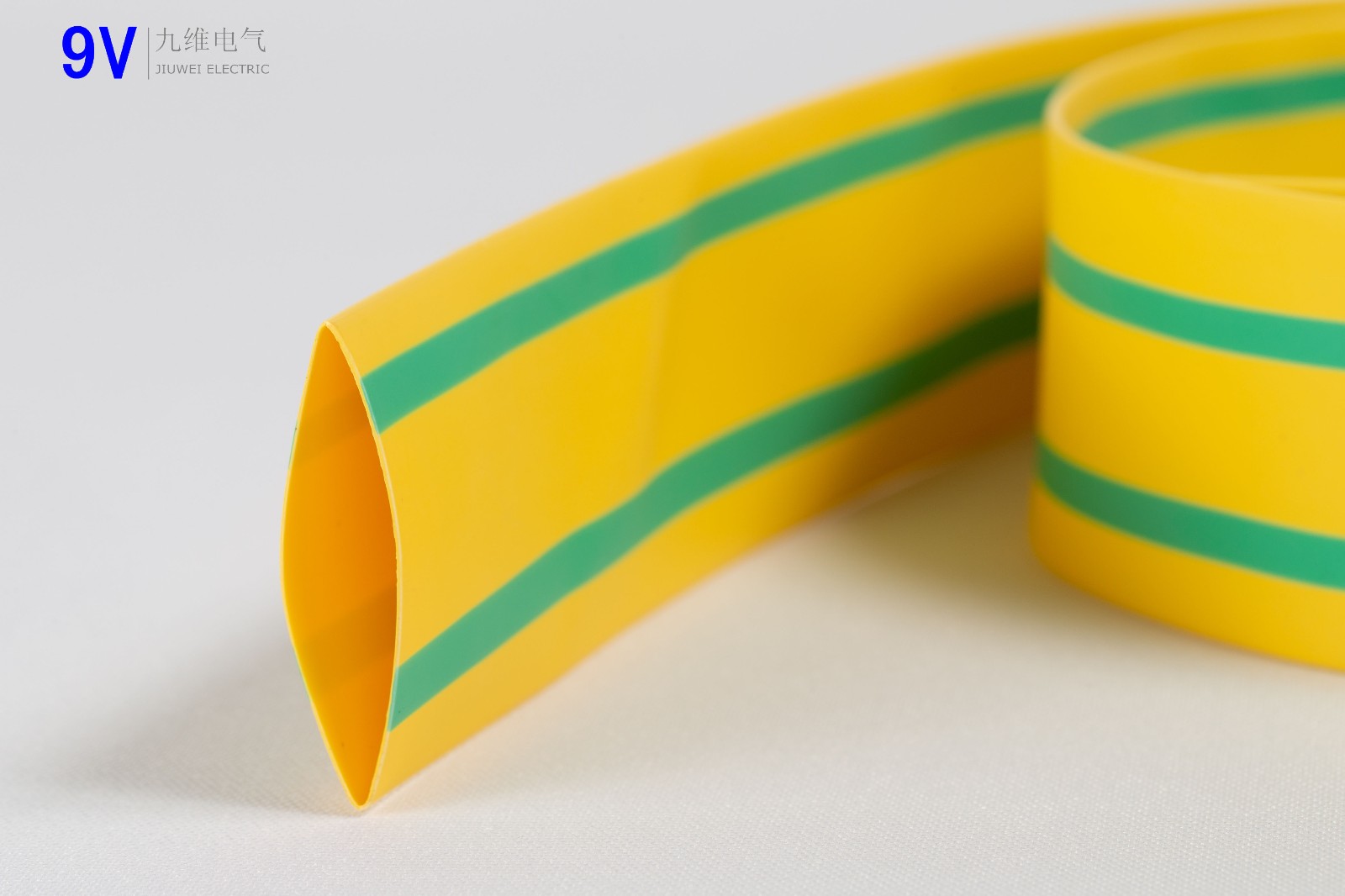

Yellow-green Heat Shrinkable Busbar Sleeve

| No. | Item | Description | ||||||||||

| 1 | Description | The yellow-green (two-color) heat-shrinkable tube is made of environmentally friendly polyolefin material, yellow-green two-color co-extrusion, and processed by the spoke clothing industry. It is widely used in the identification of the ground wire in the wire harness or cable, the identification of the special wire small busbar or the pipeline, etc. | ||||||||||

| 2 | Shrinkage ratio | 2:1, 3:1 | ||||||||||

| 3 | Shrinkage Temperature | 85℃~125℃ | ||||||||||

| 4 | Working Temperature | -55℃~125℃ | ||||||||||

| 5 | Environmental Standard | RoHS | ||||||||||

| 6 | Standard Color | yellow-green | ||||||||||

Type & Specification | |||||

Size (mm) | Before Shrink(mm) | Before Shrink(mm) | Package | ||

Inner Diameter (mm) | Wall Thickness (mm) | Inner Diameter (mm) | Wall Thickness (mm) | (m/roll) | |

Φ1.0 | 1.5±0.3 | 0.15±0.08 | ≤0.65 | 0.28±0.10 | 200 |

Φ1.5 | 2.0±0.3 | 0.18±0.08 | ≤0.85 | 0.32±0.10 | 200 |

Φ2.0 | 2.5±0.3 | 0.18±0.08 | ≤1.00 | 0.4±0.10 | 200 |

Φ2.5 | 3.0±0.3 | 0.18±0.08 | ≤1.30 | 0.4±0.10 | 200 |

Φ3.0 | 3.5±0.4 | 0.18±0.08 | ≤1.50 | 0.4±0.10 | 200 |

Φ3.5 | 4.0±0.4 | 0.22±0.08 | ≤1.80 | 0.42±0.10 | 200 |

Φ4.0 | 4.5±0.4 | 0.25±0.08 | ≤2.00 | 0.45±0.10 | 200 |

Φ5.0 | 5.5±0.4 | 0.25±0.08 | ≤2.50 | 0.55±0.10 | 100 |

Φ6.0 | 6.5±0.4 | 0.28±0.08 | ≤3.00 | 0.55±0.10 | 100 |

Φ8.0 | 8.5±0.5 | 0.28±0.10 | ≤4.00 | 0.6±0.10 | 100 |

Φ10 | 10.5±0.5 | 0.30±0.10 | ≤5.00 | 0.6±0.10 | 100 |

Φ12 | 12.5±0.5 | 0.30±0.10 | ≤6.00 | 0.65±0.10 | 100 |

Φ14 | 14.5±0.5 | 0.35±0.12 | ≤7.00 | 0.7±0.10 | 100 |

Φ15 | 15.5±0.6 | 0.40±0.12 | ≤7.50 | 0.75±0.10 | 100 |

Φ16 | 17.0±0.6 | 0.40±0.12 | ≤8.00 | 0.75±0.10 | 100 |

Φ18 | 19.0±0.7 | 0.40±0.15 | ≤9.00 | 0.8±0.15 | 100 |

Φ20 | 22.0±0.7 | 0.40±0.15 | ≤10.00 | 0.82±0.15 | 100 |

Φ22 | 24.0±0.7 | 0.40±0.15 | ≤11.00 | 0.82±0.15 | 100 |

Φ25 | 26.0±0.7 | 0.55±0.15 | ≤12.50 | 1±0.15 | 50 |

Φ28 | 29.0±0.7 | 0.55±0.15 | ≤14.00 | 1±0.15 | 50 |

Φ30 | 31.5±0.7 | 0.55±0.15 | ≤15.00 | 1.05±0.15 | 50 |

Φ35 | 36.5±0.7 | 0.55±0.15 | ≤17.50 | 1.15±0.15 | 50 |

Φ40 | 41.5±0.7 | 0.55±0.15 | ≤20.00 | 1.20±0.15 | 50 |

Φ50 | 51.0±0.7 | 0.55±0.15 | ≤25.00 | 1.20±0.15 | 25 |

Φ60 | ≥60 | 0.60±0.15 | ≤30.00 | 1.5±0.2 | 25 |

Φ70 | ≥70 | 0.65±0.15 | ≤35.00 | 1.6±0.2 | 25 |

Φ80 | ≥80 | 0.70±0.15 | ≤40.00 | 1.7±0.2 | 25 |

Φ90 | ≥90 | 0.75±0.15 | ≤45.00 | 1.9±0.2 | 25 |

Φ100 | ≥100 | 0.80±0.20 | ≤50.00 | 2.10±0.2 | 25 |

Tech Data | ||

Property Item | Test Method | Typical Value |

Tensile Strength | ASTM D2671 | ≥10.4Mpa |

Elongation At Break | ASTM D2671 | ≥200% |

Dielectric Strength | IEC 243 | ≥15kv/mm |

Volume Resistivity | IEC 93 | ≥1×1014Ω.cm |

Tensile Strength After Aging | UL224 158℃×168hr | ≥7.3 |

Elongation After Aging | UL224 158℃×168hr | ≥100% |

Heat Shock | UL224 250℃×4hr | No cracking |

Flame retardance | UL224 | VW-1 |

|  |

| Production Ability• 8 professional production lines • 7900 square meters of workshop area • dozens of cable accessories production equipment |

R&D Capabilities • many years of experience in R&D and customization of cable accessories, Professional R&D team • a number of professional technical engineers • mature professional technologies such as conductor link and electric field control. • Passed and obtained a number of qualification certifications |

|

| Honorary Certification • CE and SGS certification reports underwritten by PICC • High-tech Enterprise • Jiangsu cable accessories industry (top ten) • Jiangsu energy saving and environmental protection products |

|

| |

| Provide reasonable and professional use and matching solutions according to customer needs. After signing the contract, a special person will be responsible for process follow-up, timely control the progress, and cooperate with logistics to ensure the smooth delivery of the order. Perfect after-sales guarantee system, 30-year warranty, manuals and professional installation instructions are provided at the same time | |