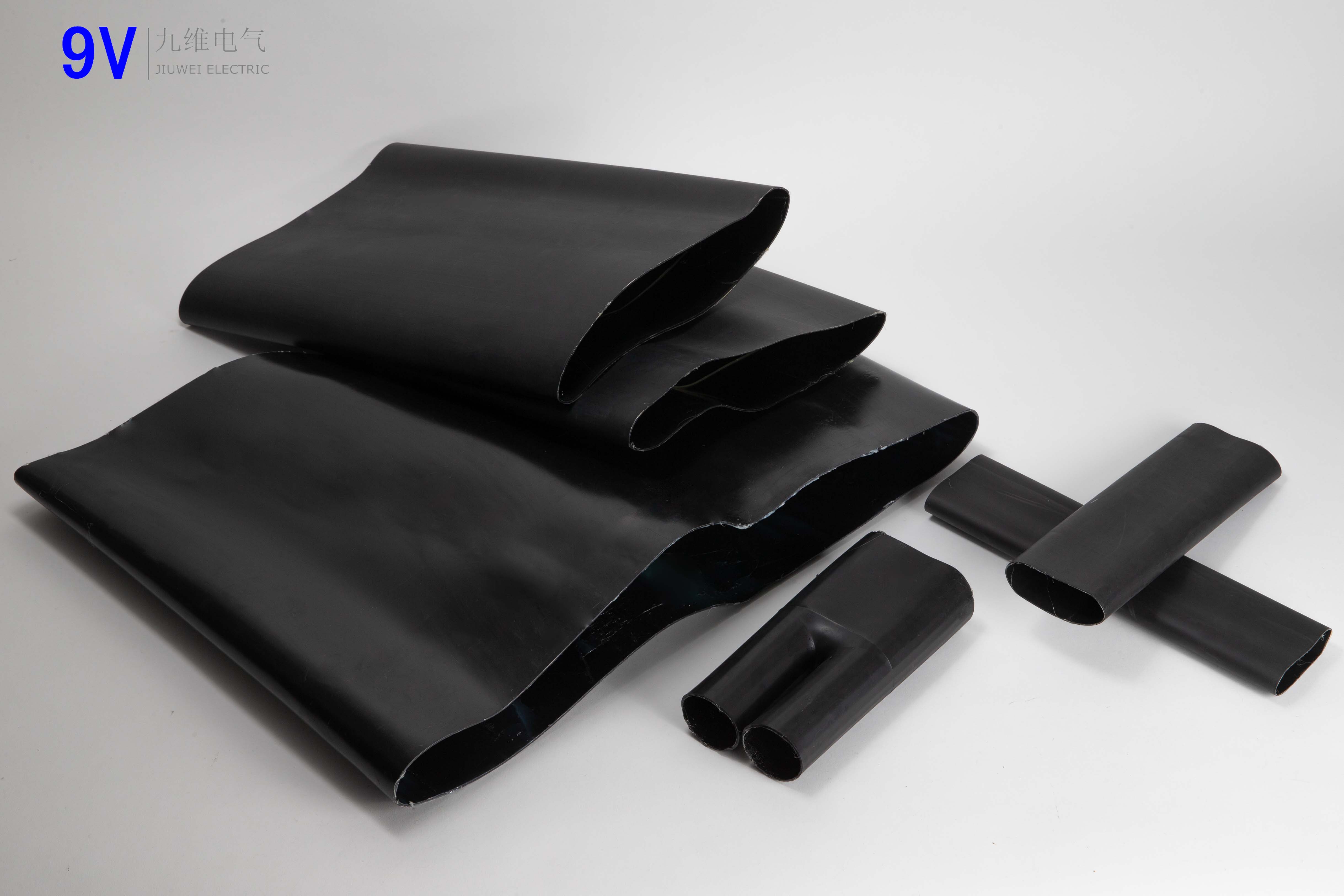

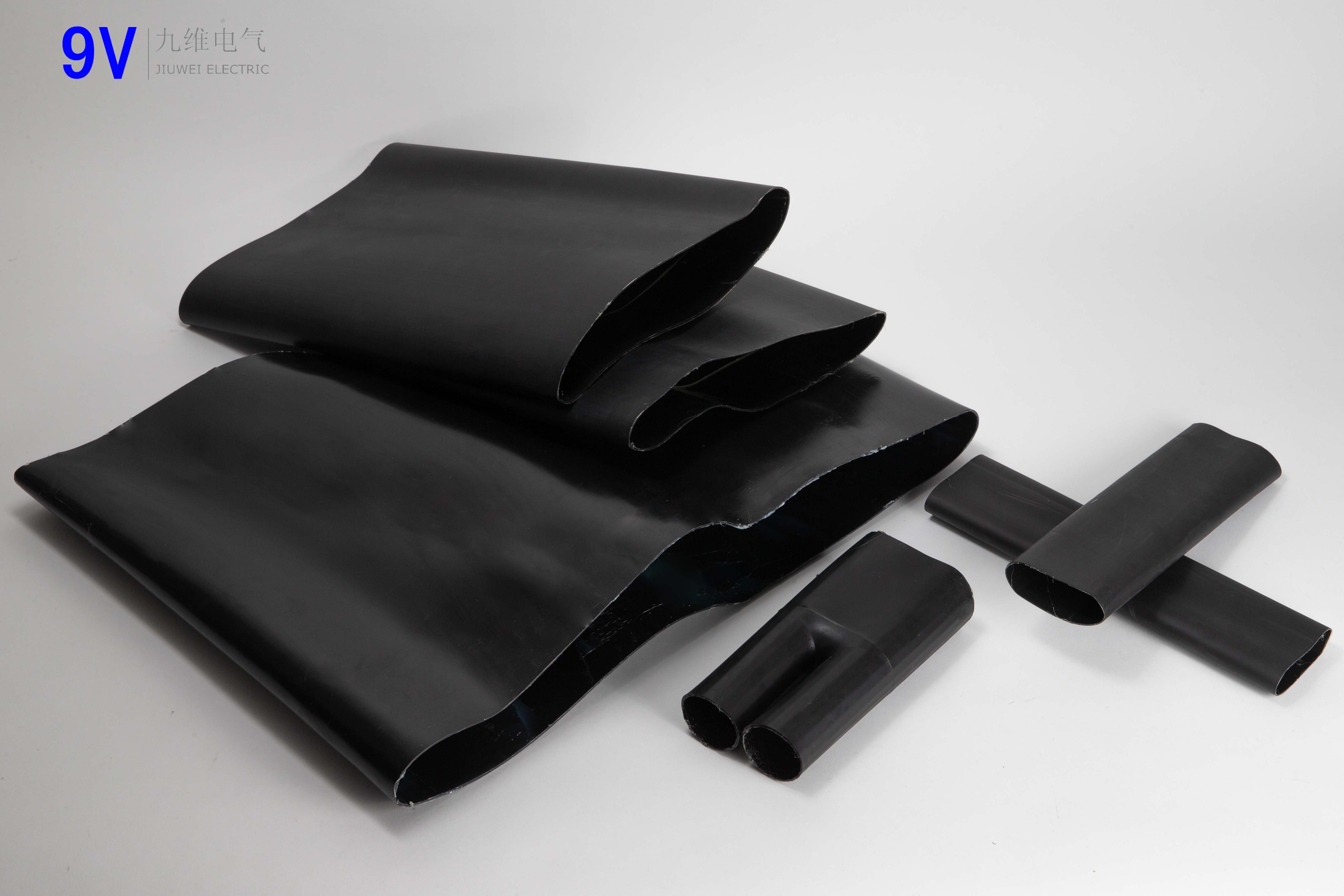

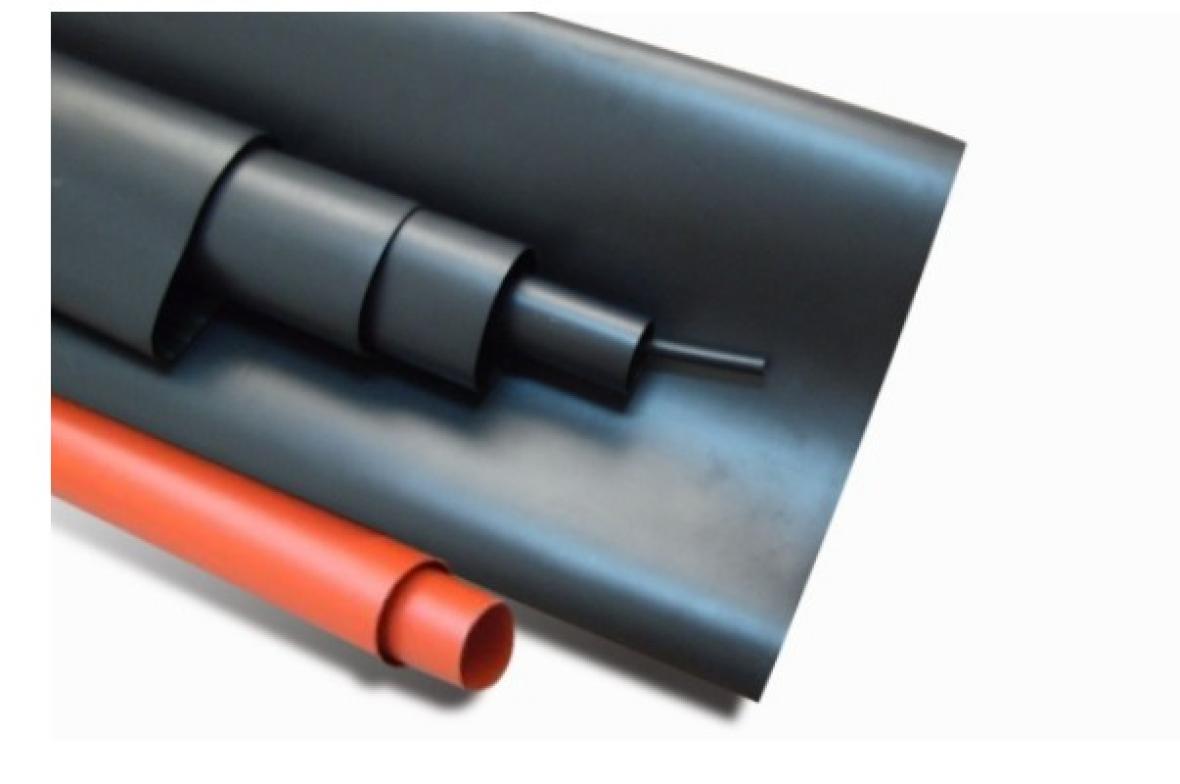

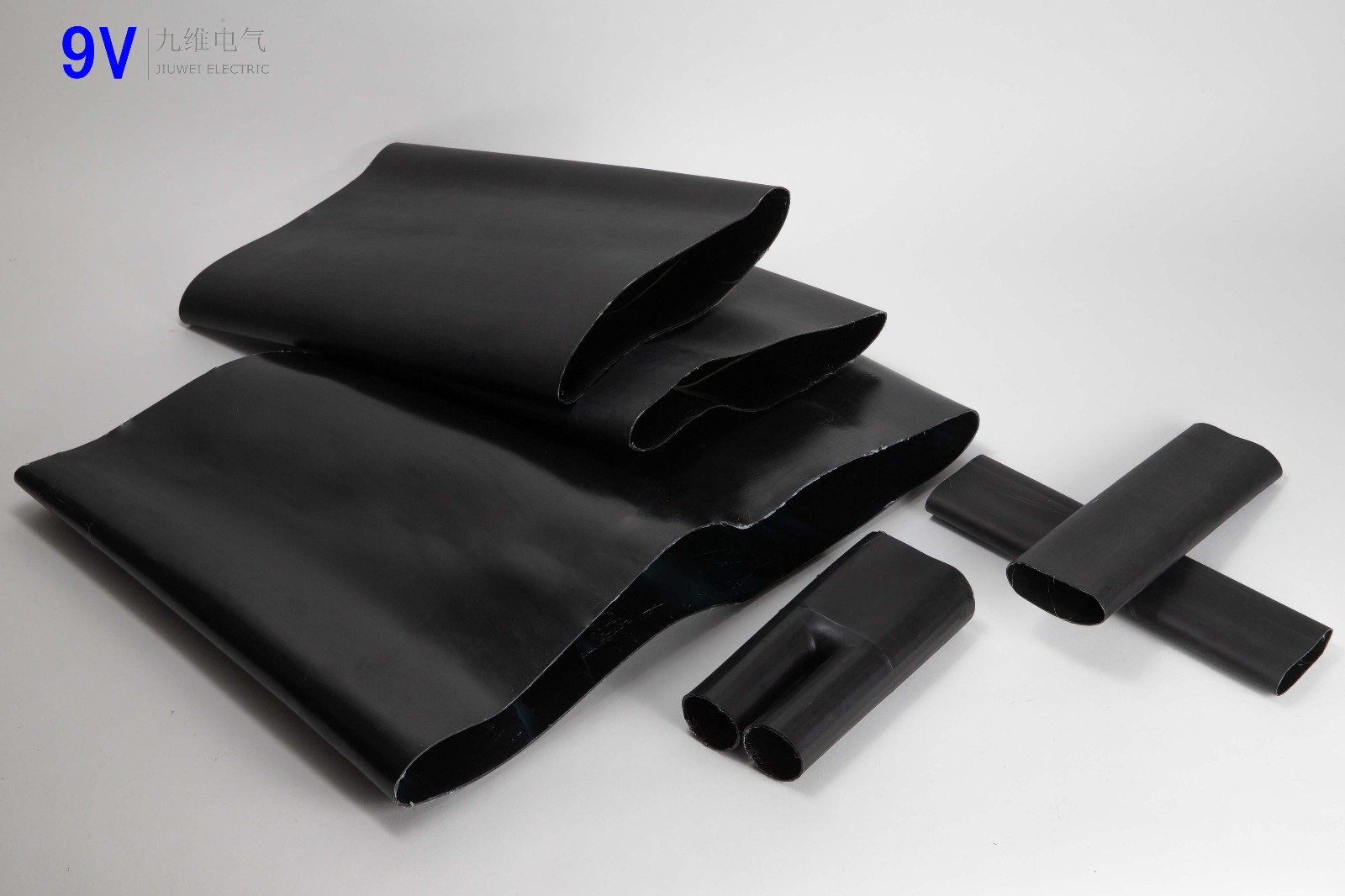

Medium/Heavy Wall Heat Shrink Tubing

| No. | Item | Description | ||||||||||||||||||

| 1 | Description | The product has good insulation, sealing, moisture-proof, waterproof, impact resistance and wear resistance. It is used for sealing and insulation protection of cable terminals or intermediate connections and other working environments that require anti-corrosion and moisture-proof. | ||||||||||||||||||

| 2 | Features | flame retardant, glued, soft, high mechanical properties, sealing, moisture-proof, waterproof, anti-aging. | ||||||||||||||||||

| 3 | Shrinkage Ratio | ≥3:1 | ||||||||||||||||||

| 4 | Shrink Speed | fast | ||||||||||||||||||

| 5 | Standard Color | black | ||||||||||||||||||

| 6 | Gluing Method | direct coating, spiral | ||||||||||||||||||

| 7 | Working Temperature | -55°C~105°C | ||||||||||||||||||

| 8 | Shrinkage Temperature | 85°C~125℃ | ||||||||||||||||||

Type & Specification | |||||||||

Item No. | VZG-Medium Wall | VHG1-Heavy Wall | VTG(6X)-Heavy Wall | ||||||

Size (mm) | ID Before Shrink (mm) | ID Aafter Shrink (mm) | THK After Shrink (mm) | ID Before Shrink (mm) | ID After Shrink (mm) | THK After Shrink (mm) | ID Before Shrink (mm) | ID After Shrink (mm) | THK After Shrink (mm) |

Φ9 | 9 | 3 | 1.6 | 9 | 3 | 1.8 | 19 | 3.2 | 3.2 |

Φ12 | 12 | 4 | 1.8 | 12 | 4 | 2.4 | 33 | 5.5 | 3.4 |

Φ22 | 22 | 6 | 2.3 | 22 | 6 | 2.7 | 45 | 7.4 | 3.6 |

Φ33 | 33 | 8 | 2.5 | 33 | 8 | 3.2 | 51 | 8.3 | 4.3 |

Φ40 | 40 | 12 | 2.6 | 40 | 12 | 4.1 | 70 | 11.7 | 4.8 |

Φ55 | 55 | 16 | 2.7 | 55 | 16 | 4.1 | 90 | 17.1 | 4.8 |

Φ65 | 65 | 20 | 2.9 | 65 | 20 | 4.1 | 120 | 22.9 | 4.8 |

Φ75 | 75 | 22 | 2.9 | 75 | 22 | 4.1 | 235 | 40.0 | 4.8 |

Φ85 | 85 | 25 | 2.9 | 85 | 25 | 4.3 | |||

Φ95 | 95 | 30 | 3.0 | 95 | 30 | 4.3 | |||

Φ105 | 105 | 33 | 3.0 | 105 | 33 | 4.3 | |||

Φ115 | 115 | 35 | 3.0 | 115 | 35 | 4.3 | |||

Φ130 | 130 | 40 | 3.0 | 130 | 40 | 4.3 | |||

Φ140 | 140 | 43 | 3.0 | 140 | 43 | 4.3 | |||

Φ160 | 160 | 50 | 3.0 | 160 | 50 | 4.3 | |||

Φ180 | 180 | 60 | 3.0 | 180 | 60 | 4.3 | |||

Φ200 | 200 | 65 | 3.0 | 200 | 65 | 4.3 | |||

Φ235 | 235 | 70 | 3.0 | 235 | 70 | 4.3 | |||

Φ265 | 265 | 75 | 3.0 | 265 | 75 | 4.3 | |||

Tech Data | ||

Property Item | Test Method | Typical Value |

Operating Temperature | IEC216 | -55℃~+110℃ |

拉伸强度 | ASTMD 2671 | ≥14MPa |

断裂伸长率 | ASTMD 2671 | ≥400% |

Tensile Strength After Ageing (150℃/168h) | ASTMD 2671 | ≥12MPa |

Elongation After Ageing (150℃/168h) | ASTMD 2671 | ≥300% |

Longitudinal Shrink Ratio | UL 224 | 0~10% |

Dielectric Strength | IEC243 | ≥20KV/mm |

Volume Resistivity | IEC93 | ≥10Ω.cm |

Thermal shock | ASTMD 2671 | No cracking |

|

|

| Production Ability• 8 professional production lines • 7900 square meters of workshop area • dozens of cable accessories production equipment |

R&D Capabilities • many years of experience in R&D and customization of cable accessories, Professional R&D team • a number of professional technical engineers • mature professional technologies such as conductor link and electric field control. • Passed and obtained a number of qualification certifications |

|

| Honorary Certification • CE and SGS certification reports underwritten by PICC • High-tech Enterprise • Jiangsu cable accessories industry (top ten) • Jiangsu energy saving and environmental protection products |

|

| |

| Provide reasonable and professional use and matching solutions according to customer needs. After signing the contract, a special person will be responsible for process follow-up, timely control the progress, and cooperate with logistics to ensure the smooth delivery of the order. Perfect after-sales guarantee system, 30-year warranty, manuals and professional installation instructions are provided at the same time | |