Type & Specification | ||||||||||||||||

| Type of Tape | Model | Advantage | Benefit | Standard | ||||||||||||

| Electrical stress control tape | 9220 | Special high dielectric material, stable high temperature performance | Stress evacuation runs reliably for a long time | Import | ||||||||||||

| Semiconducting tape | 913 | Low resistance, low heat generation, self-melting, stable performance at high temperature | Durable and reliable electric field shielding | Import | ||||||||||||

| High voltage insulation self-adhesive tape | 923 | Excellent self-fusion | Small partial discharge and reliable operation | Import | ||||||||||||

| Waterproof tape | 9228 | Excellent thermal aging resistance and ozone resistance | Strong covering, durable waterproof | Import | ||||||||||||

| Waterproof cement | 9166 | Soft, flexible and sticky | Good sealing effect | Import | ||||||||||||

| PVC tape - Red, Yellow, Green | 8600 | Excellent ozone resistance and fading resistance | Permanent identification | Domestic | ||||||||||||

| Armour tape | Armor Wrap | High quality glass fiber and water curing | High mechanical strength | Domestic | ||||||||||||

⒈Tech Data - Semiconducting tape | ⒊Tech Data - High voltage insulation self-adhesive tape | |||||||||||||||

| Elongation at Break | 900% | Minimum elongation at break | 900% | |||||||||||||

| Tensile strength at break | 3MPa | Tensile strength at break | 3MPa | |||||||||||||

| Volume Resistivity | 10Ωxcm | Dielectric constant | 2.8 | |||||||||||||

| Working Temperature | -40℃~100℃ | Dissipation factor (50Hz) | 0.005 | |||||||||||||

| ⒉Tech Data - Sealing tape | Dielectric strength | 42KV/mm | ||||||||||||||

| Volume Resistivity | 1 x 1013MΩ | |||||||||||||||

| Dielectric constant | 3.1 | Bibulous rate | 0.05% | |||||||||||||

| Dissipation factor (50Hz) | 0.025 | Working Temperature | ||||||||||||||

| Dielectric strength | 16KV/mm | Minimum | -40℃ | |||||||||||||

| Volume Resistivity | 1 x 1013MΩ | Maximum | 100℃ | |||||||||||||

| Bibulous rate | 0.10% | |||||||||||||||

Operating parameters | ||||||||||||||||

| Item No. | Rated Voltage | 5 minutes power frequency withstand voltage | Universal cable cross section | Working Temperature | ||||||||||||

| VRBJ-10KV | 10KV | 39KV | 25~630mm² | Long-term 90℃. Overload 130℃ | ||||||||||||

| VRBJ-20KV | 20KV | 54KV | 35~630mm² | Long-term 90℃. Overload 130℃ | ||||||||||||

| VRBJ-35KV | 35KV | 117KV | 50~630mm² | Long-term 90℃. Overload 130℃ | ||||||||||||

Tech Data | ||||||||||||||||

| Test Item | Technical Requirements (10KV) | Technical Requirements (35KV) | Test Result | |||||||||||||

| AC withstand voltage test | 39KV, 5min, No breakdown | 117KV, 5min, No breakdown | Pass | |||||||||||||

| Partial discharge test at room temperature | 15KV,<10pC | 45KV,<10pC | Pass | |||||||||||||

| Impulse voltage test | 95℃~100℃, ±95KV, 10 times each without breakdown | 95℃~100℃, ±200KV, 10 times each without breakdown | Pass | |||||||||||||

| Constant pressure load cycle test in air | 22KV, 95℃~100℃, heating for 5h per cycle, cooling for 3h. No breakdown for a total of 30 cycles | 65KV, 95℃~100℃, heating for 5h per cycle, cooling for 3h. No breakdown for a total of 30 cycles | Pass | |||||||||||||

| Constant pressure load cyclic test in water | 22kV, 95℃~100℃, heating for 5h per cycle, cooling for 3h. No breakdown for a total of 30 cycles | 65KV, 95℃~100℃, heating for 5h per cycle, cooling for 3h. No breakdown for a total of 30 cycles | Pass | |||||||||||||

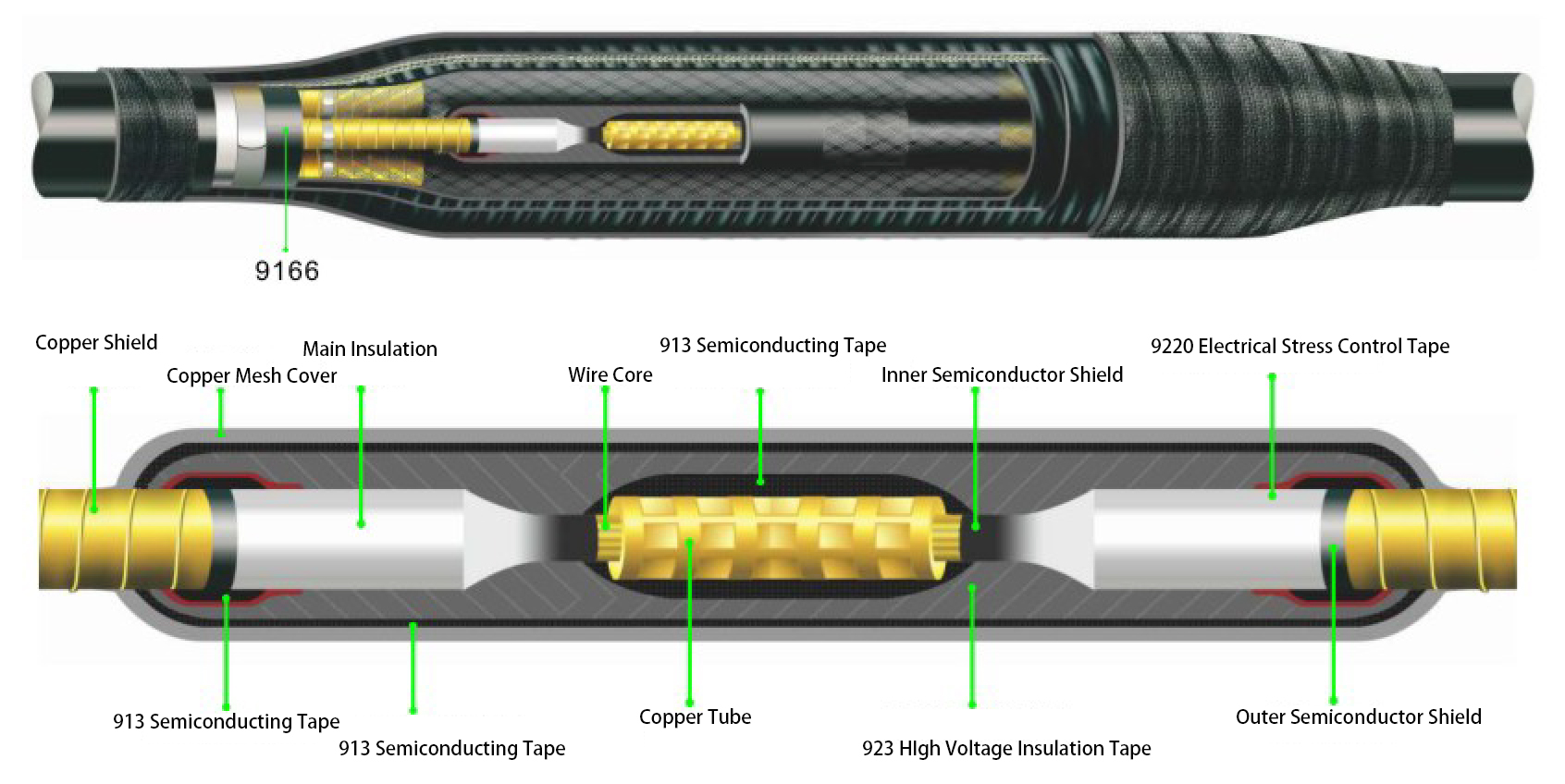

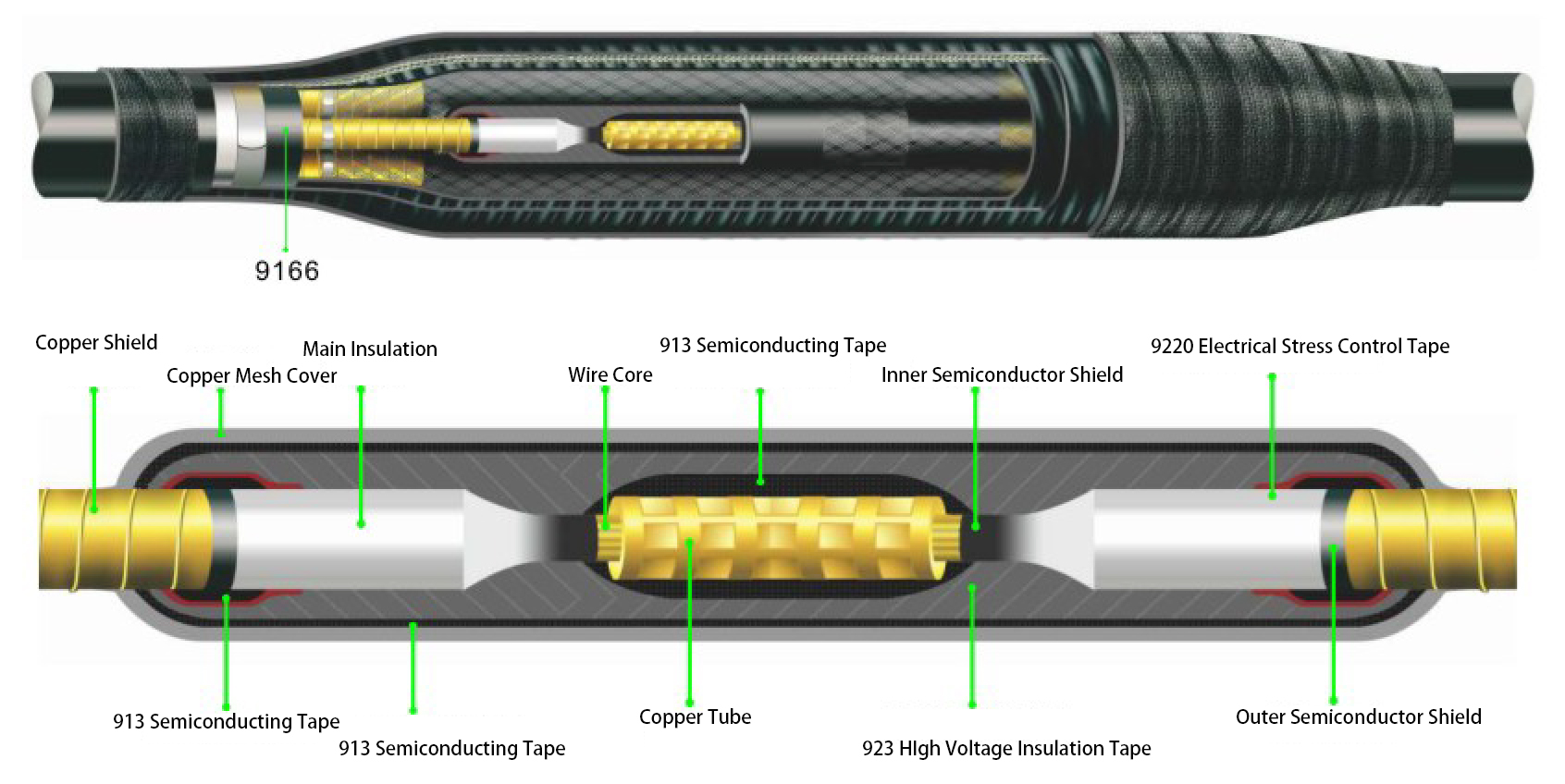

Sectional View | ||||||||||||||||

| ||||||||||||||||

| • 913 semi-conductive tape restores the inner and outer semi-conductive shielding of the cable • 9220 electrical stress control tape equilibrium uniform electric field • 923 high voltage insulation tape to restore the main insulation of the cable | • Copper mesh sleeve to restore the metal shield • 9228 and 9166 restore cable sealing waterproof • 9228 and armor tape restore cable sheath | |||||||||||||||

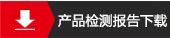

Special Application | ||||||||||||||||

Due to the special production process of wrapped intermediate joints, they can be used for the extension of cables with insufficient spare capacity or for the production of intermediate joints with different cross-sections.

| ||||||||||||||||

Application Case | ||||||||||||||||

| ||||||||||||||||

| Production Ability• 8 professional production lines • 7900 square meters of workshop area • dozens of cable accessories production equipment |

R&D Capabilities • many years of experience in R&D and customization of cable accessories, Professional R&D team • a number of professional technical engineers • mature professional technologies such as conductor link and electric field control. • Passed and obtained a number of qualification certifications |

|

| Honorary Certification • CE and SGS certification reports underwritten by PICC • High-tech Enterprise • Jiangsu cable accessories industry (top ten) • Jiangsu energy saving and environmental protection products |

|

| |

| Provide reasonable and professional use and matching solutions according to customer needs. After signing the contract, a special person will be responsible for process follow-up, timely control the progress, and cooperate with logistics to ensure the smooth delivery of the order. Perfect after-sales guarantee system, 30-year warranty, manuals and professional installation instructions are provided at the same time | |